Scrap steel crushing, sorting and recycling production line

【Feed size】:Less than the diameter of the metal shredder feed port

【Discharge size】:1cm-5cm diameter metal ball

【Production】:1-3 tons per hour

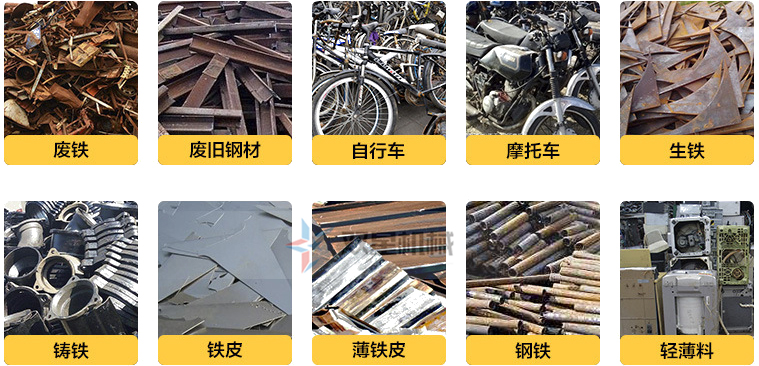

【Applicable materials】:Various metal raw materials such as scrap iron, scrap steel, scrap iron drums, colored steel tiles, household appliances, scrap bicycles, thin iron sheets, raw aluminum aluminum alloys, cans, etc.

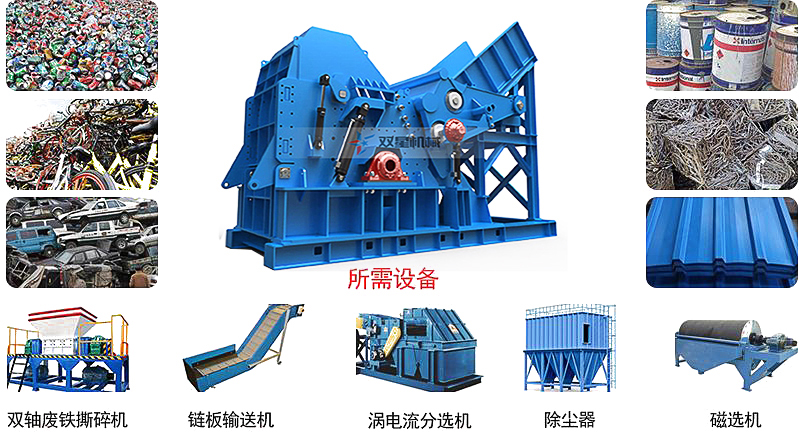

【Equipment Composition】:Double axis shredder metal crusher eddy current separator belt conveyor

Making phone calls:13592521219

Production line composition

device solutions

Waste steel production line processing materials:

Production Line Process:

Production line process: feeding conveyor (chain plate conveyor optional) → double shaft shredder → scrap steel crusher → discharge conveyor → magnetic separator → eddy current separator → discharge conveyor → dust collector

△ 您可能对以下产品感兴趣?

- 全部评论(0)