eddy current separator

【Motor Power】:5kw-15kw

【productive power】:0.6T/h-15T/h

【Discharge size】:Determined by the crushing effect

【Supporting equipment】:Metal crusher host, dual axis shredder (optional), conveyor belt, magnetic sorting machine, eddy current sorting machine, dust collector (optional), etc.

【Applicable materials】:Separation of various metal materials such as scrap iron, scrap aluminum, scrap copper, etc.

【The price of eddy current separator】:Different models have different prices, please call for consultation

Telephone:13592521219

01. Equipment

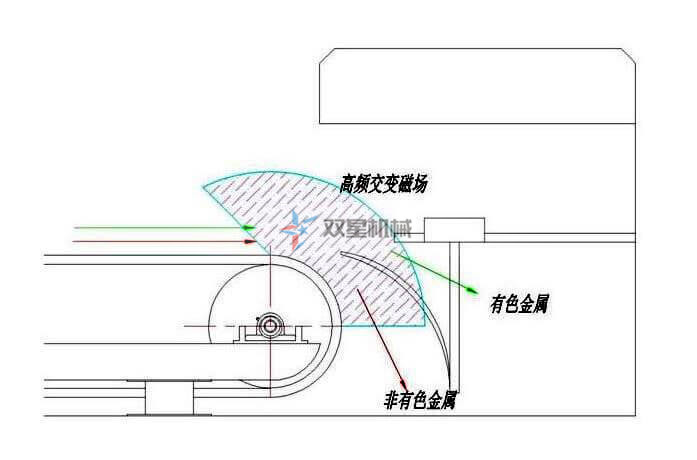

Eddy current sorting machines, also known as eddy current sorting machines, metal sorting machines, etc., can separate non-ferrous metals such as copper and aluminum from various metal crushing mixed materials, and can also be promoted and applied in the field of environmental protection, especially in the non-ferrous metal recycling industry. The eddy current sorting machine is designed based on the principle of induced current generated by conductors in high-frequency alternating magnetic fields. During operation, a high-frequency alternating magnetic field is generated on the surface of the sorting magnetic roller. When conductive non-ferrous metals pass through the magnetic field, eddy currents are induced inside the non-ferrous metal. This eddy current itself generates a magnetic field opposite to the original magnetic field direction. Non ferrous metals (such as copper, aluminum, etc.) will leap forward along their transportation direction due to the repulsive force of the magnetic field, achieving separation from other non-conductive or non-metallic substances, To achieve the purpose of sorting.The eddy current sorting machine is mainly used for the crushing and recycling process of various waste materials such as circuit boards, waste doors and windows, waste cars, and waste household appliances. Through the eddy current sorting machine, various weakly magnetic non-ferrous metal materials such as copper, aluminum, tin, zinc, and stainless steel can be effectively separated from the crushed materials, which has high economic and environmental value.

02. Working principle

The feeding requirements of the eddy current sorting machine must be matched with a suitable vibrating feeder to ensure that the materials evenly pass through the sorting machine without interfering with each other. This will cause the distance between the materials to be roughly equal. If the particle size difference is significant, it will form the phenomenon of small particle materials entering the non-metallic discharge hopper. No overlapping of materials is allowed. If the nonferrous metals are superimposed on the nonmetal, the magnetic field intensity will be extremely attenuated due to the increased thickness of scrap metal, which will cause the nonferrous metals to fall into the scrap metal discharge hopper; If non-metals are stacked on top of non-ferrous metals, it may increase the weight of the object, causing both non-ferrous metals and non-metals to not be thrown out and fall into the non-metallic discharge hopper. It may also be thrown into the non-ferrous metal discharge hopper at the same time.

1. The eddy current sorting machine consists of two parts: the main body of the sorting machine and the power control cabinet;

2. The main body of the eddy current sorting machine consists of a sorting system, a motor, and a protective cover for the body bracket.

3. The sorting system is the core of the equipment, consisting of permanent magnet rollers, conveyor belts, conveyor belt power rollers, and deceleration motors.

03. Equipment advantages

1. The eddy current sorting machine is easy to install and use, with high separation efficiency, and uses strong magnetic rollers to save energy;

2. The feed of the vortex separator is uniform, and uneven distribution will affect the sorting effect;

3. The vortex current sorting machine has a compact, reliable, and reasonable structure, which is easy to maintain and maintain;

4. The eddy current sorting machine has strong repulsive force and is adjustable, with strong adaptability;

5. The sorting particle size range is large, and non magnetic non-ferrous metals with particle sizes greater than 2mm can be sorted.

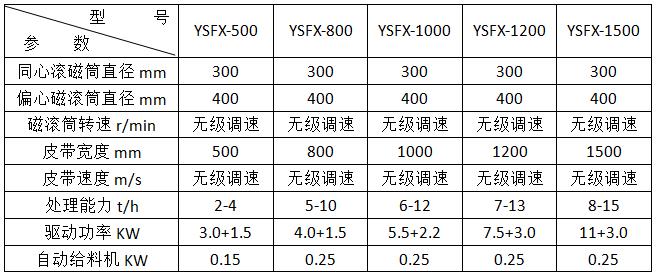

04. Equipment price and model

说点什么吧

- 全部评论(0)

还没有评论,快来抢沙发吧!