Special topic on scrap steel and aluminum crusher

Scrap steel is widely recognized as an ideal raw material for steelmaking, but its composition is complex and there are many impurities such as non-ferrous metals, non-metals, and garbage. In order to process clean waste steel, higher requirements have been put forward for waste steel processing equipment. However, currently commonly used equipment such as packaging machines and shearing machines cannot meet the requirements of steel mills for "fine material feeding into the furnace" due to the lack of separation and purification devices.

经过 废钢破碎机 The processed crushed materials have high density, purity, and almost no impurities. When steel mills and other manufacturing enterprises use crushed materials to remelt into new products, the unit energy consumption is low, the output is high, and the comprehensive economy is obvious!

The scrap steel and aluminum crusher is widely recognized as an ideal equipment for treating scrap steel.

| Scrap steel and aluminum crusher | Metal Baler | Metal shearing machine | |

|---|---|---|---|

| shape |  |

|

|

| Disposal | crush | pack | shear |

| function | various | single | single |

| feeding method | conveyor | artificial | artificial |

| finish product |  |

|

|

| effect | excellent:High density, good smoothness, and few impurities | wrong:Excessive impurities, paint adhesion, and high smelting cost | wrong:Low density, high impurities, paint adhesion, and high transportation costs |

| profit | tall | low | low |

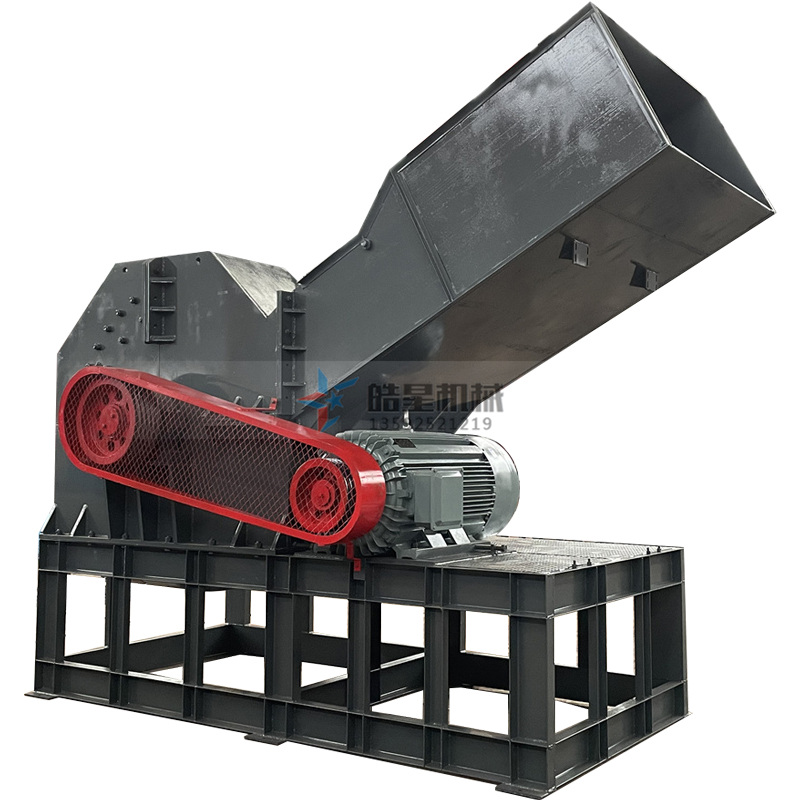

The main engine shell is made of ultra-thick steel plate, with a lining made of high manganese cast steel, which can be replaced;

The main engine rotor has 11 steel discs installed on the horizontal shaft, with 6 pin shafts distributed around the steel discs and 10 hammer heads suspended axially;

The spindle is supported by ball bearings, forced lubrication and cooling by circulating oil, and equipped with temperature sensors;

The feeding port is equipped with a hydraulic roller feeding device, located one high and one low, rotating in the same direction, which can flatten large loose materials and feed them into the machine. The speed of the roller determines the feeding speed, which is controlled by the load current feedback of the host motor, achieving automatic adjustment to ensure that the host is in a stable load state;

The host is equipped with a safety door, which allows for the discharge of non shatterable objects after they enter the host to avoid damage to the host.

The core principle of the scrap steel and aluminum crusher is to use a hammer to strike and crush scrap steel. Driven by a high-speed and high torque motor, the hammer head on the rotor of the main machine takes turns hitting the material to be crushed into the crushing chamber, tearing it apart into compliant pieces through the space formed between the lining plate and the hammer head.

-

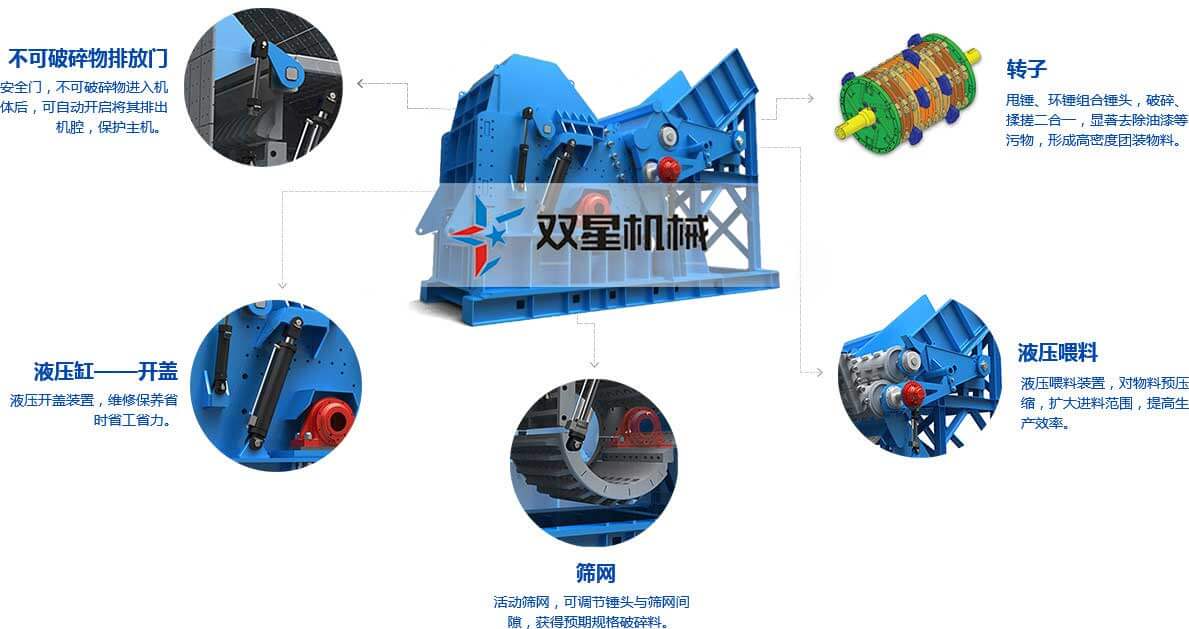

Hydraulic cover opening

Hydraulic cover openingHydraulic cover opening device, time-saving and labor-saving for replacement and maintenance.

-

Hydraulic feeding

Hydraulic feedingThe material pressing device pre compresses the material, expands the feeding range, and improves production efficiency.

-

exit

exitSet up safety doors to prevent debris from entering the crushing chamber and allowing it to be discharged from the machine to avoid damaging the crusher.

-

Scrap steel and aluminum crusher

Scrap steel and aluminum crusherThe fuselage is reinforced by extra thick steel plate and slant support, which can ensure the overload requirements of the machine for strong crushing.

-

Lining plate

Lining plateThe lining plate is made of high manganese alloy steel material, which improves its service life.

-

Hammer head

Hammer headThe hammer head is made of high manganese alloy steel material, which improves its service life.

-

Host housing

Host housingThe main body shell is welded with ultra-thick steel plates, with a thickness of 100mm to ensure the strength of the main body.

As for the scrap steel and aluminum crusher, the excellent performance during tens of thousands of hours of operation stems from the strict requirements on the production line and the sense of professional responsibility upheld by the manufacturer.

Haoxing Heavy Industry always keeps in mind the expectations of every customer, and through strict screening of components and strict monitoring of production processes, every scrap steel and aluminum crusher has become a reliable starting point for operation.