-

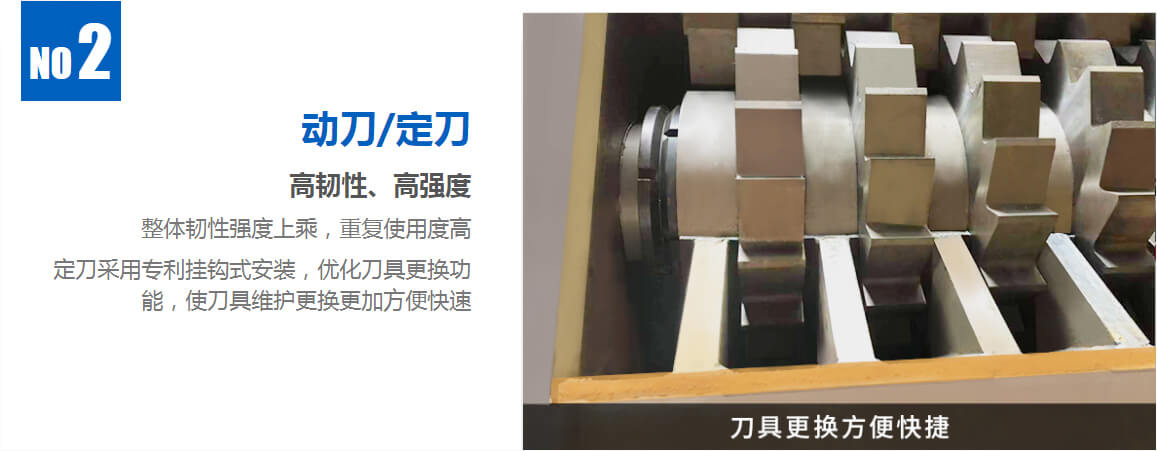

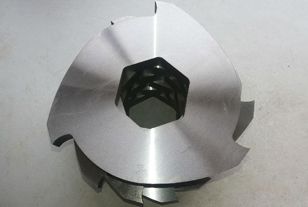

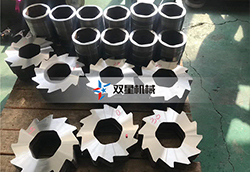

Imported alloy blade

The blade is made of imported high hardness and wear-resistant special alloy steel, which has good wear resistance, strong impact resistance, strong cutting performance, and durability.

The blade is made of imported high hardness and wear-resistant special alloy steel, which has good wear resistance, strong impact resistance, strong cutting performance, and durability. -

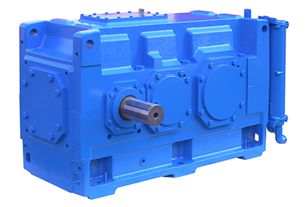

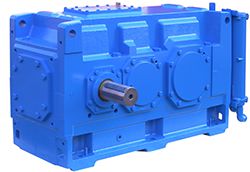

Reduction gearbox

Compared to soft tooth reduction boxes, their gears undergo processes such as quenching and tempering, carburizing and quenching, and grinding, resulting in high transmission efficiency, smooth operation, and low noise; The advantages of small size, light weight, long service life, and high load-bearing capacity.

Compared to soft tooth reduction boxes, their gears undergo processes such as quenching and tempering, carburizing and quenching, and grinding, resulting in high transmission efficiency, smooth operation, and low noise; The advantages of small size, light weight, long service life, and high load-bearing capacity. -

motor

First tier brand Beijing Huade. Compared with electric motors, hydraulic motors have the same power, smaller volume, lighter weight, and are easy to obtain larger torque, achieve a wide range of stepless speed change, quickly and smoothly achieve forward and reverse transmission, and are easy to prevent overload accidents.

First tier brand Beijing Huade. Compared with electric motors, hydraulic motors have the same power, smaller volume, lighter weight, and are easy to obtain larger torque, achieve a wide range of stepless speed change, quickly and smoothly achieve forward and reverse transmission, and are easy to prevent overload accidents.

-

Electrical control cabinet

The electrical control cabinet uses Siemens and Schneider Electric as electrical stability support to achieve intelligent operation of the equipment.

The electrical control cabinet uses Siemens and Schneider Electric as electrical stability support to achieve intelligent operation of the equipment. -

box

The split box design is convenient for maintenance and replacement.

The split box design is convenient for maintenance and replacement. -

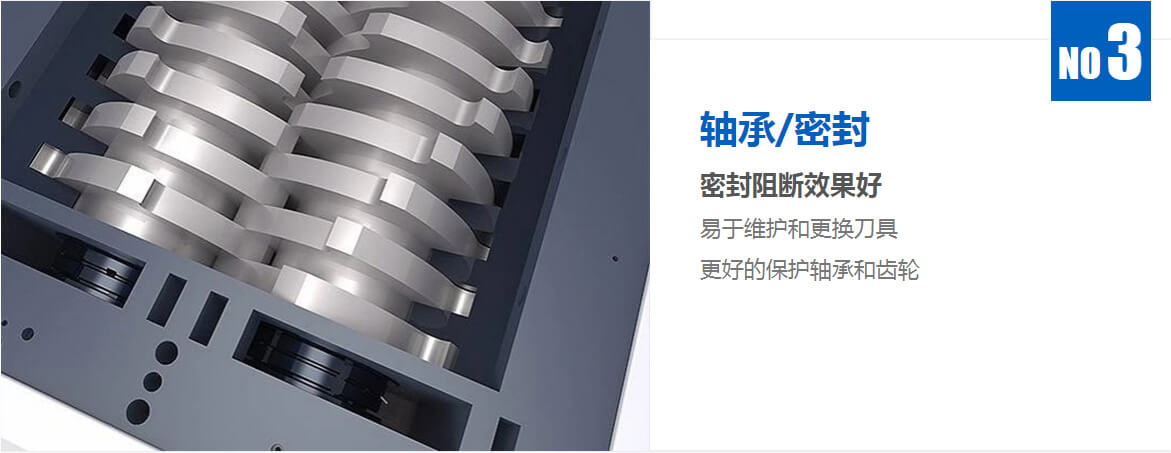

bearing

The original imported SKF brand bearings from Sweden can withstand greater impact force and are durable.

The original imported SKF brand bearings from Sweden can withstand greater impact force and are durable. -

External bearing seat

External bearing design, fully sealed, effectively waterproof and dustproof, extending the service life of the bearing.

External bearing design, fully sealed, effectively waterproof and dustproof, extending the service life of the bearing.